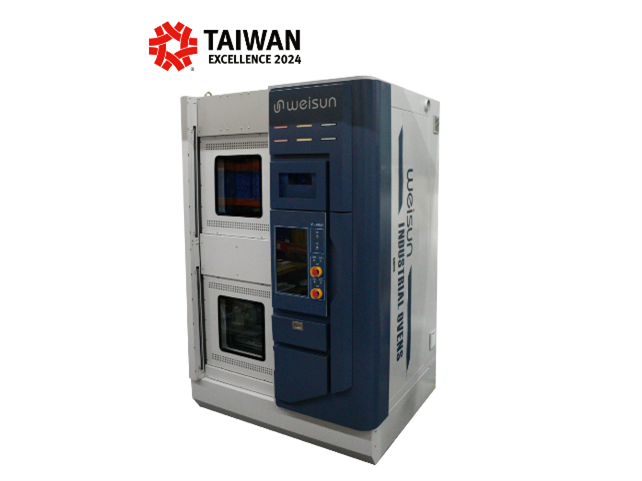

Application and promotion of plasma products

▲ Creating Nano Technologies Coating、Plasma

Since its establishment,

CNT has been committed to

the development of AP plasma, LP plasma and

coating OEM with its excellent R&D capabilities and

high quality pursuit. After years of hard work, CNT

has achieved the best quality for different types of

products through perfect product solutions, and has

been recognized by numerous manufacturers.

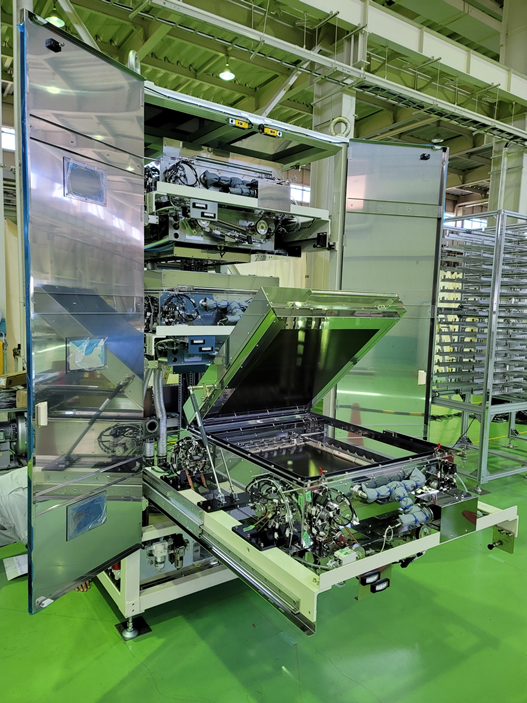

AP plasma can quickly remove organic pollutants in

the atmospheric environment, achieve the function

of component surface cleaning and improvement,

and effectively improve the product reliabili ty of

component packaging (LED), surface adhesion, liquid

crystal panel industry (TFT, STN, OLED, LTPs) and

circuit printing (PCB). A P plasma treatment has many

excellent characteristics, such as high treatment

efficiency, fast tr eatment speed, good unifor mity, no

component damage caused by the treatment of

metal substrate materials, simple equipment

operation and adjustable treatment distance. It can

also be integrated into the I n Line production line.

The size of the wide range

AP plasma equipment in the plant is from 100mm to the largest 10.5

generation production line in the industry. The

product size can also be customized to meet the

needs of clients.

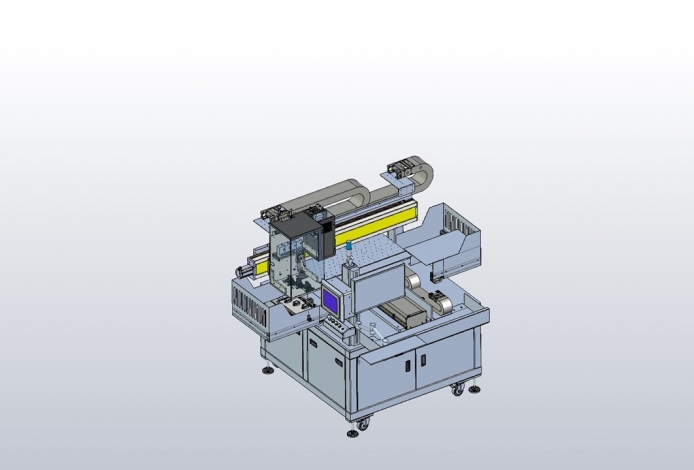

LP plasma has good functions in surface activation,

modification, grafting, roughening and cleaning

be fore printing or adhesion of various substrates,

which can effectively improve the reliability of LCM,

IC component packaging, LED packaging,

optoelectronic components and electronic

component packaging. L P plasma treatment has

many excellent characteristi cs, such as good

treatment uniformity, low ion energy, not easy to

damage the substrate, no pollution of electrode and

substrate, high density plasma source, fast treatment

speed, high cleaning efficiency, full automatic and

easy operation, which can be ad justed according to

customer needs.

Coating OEM

can provide titanium nitride (TiN),

chromium nitride (AlCrN), high aluminum (AlTiN),

medium aluminum (TiAlN), high aluminum titanium

chromium (AlTiCrN), TiX H, nano multilayer

composite, Ta C, diamond like carbon (DLC),

antistatic dissipative diamond like carbon (ESD DLC),

high temperature resistant diamond like carbon film

(DLC), rainbow diamond (Rainbow Diamond) and

other coating processes. It can be used in cutting

tools, punching tools, stamping and shea ring dies to

increase the service life of the dies and assist in heat

dissipation, prevent scratches on optical lenses, and

apply to many applications such as biomedical

materials. In terms of coating OEM, CNT has been

mass produced for many years, and has been

affirmed and certified by customers for many years

with good stability and reliability.

Creating 's plasma technology has a solid domestic

position. At present, the equipment is mainly

exported to China , and the cutting tools are mainly

exported to Eastern European countries (Poland,

etc.), so we hope to take this platform to promote our

products to overseas markets, deepen brand

recognition abroad, and expand CNT team to the

international market.